Gear pumps and motors 1600

Cast iron body; max working pressure 170 bar; max driving speed 3.000 rpm, displacement from 12 up to 41 cc; SAE mounting flanges and driving shafts.

Gear and pumps and motors; hydrostatic transmissions; directional control valves; flow dividers; hydraulic and industrial filters; heat exchangers and cooling systems; hydraulic accumulators.

Select the family of products you need, to see the technical features that matter to you in detail.

Cast iron body; max working pressure 170 bar; max driving speed 3.000 rpm, displacement from 12 up to 41 cc; SAE mounting flanges and driving shafts.

Cast iron body; max working pressure 250 bar; max driving speed 3.000 rpm; displacement from 22 up to 62 cc/rev; SAE mounting flanges and driving shafts

.Cast iron body; max working pressure 250 bar; max driving speed 3.000 rpm; displacement from 53 up to 110 cc; SAE mounting flanges and driving shafts

.Cast iron body; max working pressure 250 bar; max driving speed 3.000 rpm; displacement from 87 up to 155 cc; SAE mounting flanges and driving shafts

.Cast iron body; max working pressure 175 bar; max driving speed 3.000 rpm; displacement from 132 up to 306 cc; SAE mounting flanges and driving shafts

.Cast iron body; max working pressure 280 bar; max driving speed 3.000 rpm, displacement from 45 up to 200 cc; SAE mounting flanges and driving shafts

.

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. nominal pressure 300 bar, 350 bar peak; driving speed: 700 rpm min., 3.600 rpm max.; SAE driving shafts and mounting flanges; optional rear PTO

.

Variable displacement pumps in closed loop; available in 3 max. displacement sizes of 14, 18, 22 cc/rev; lever control spring returned to neutral; max. nominal pressure 170 bar, 250 bar peak; driving speed: 700 rpm min., 3.600 rpm max.; SAE driving shafts and mounting flanges

.

Fixed displacement; can operate in open and closed loop; available in 2 design and 6 displacements of 21, 28, 35, 46, 50, 64 cc/rev; max. operating pressure 250 bar, peak 350 bar; max. output speed 3.600 rpm; SAE shafts and flanges.

Variable displacement; can operate in open or closed loop; max. displacement of 46, 50 e 64 cc/rev; operating pressure 300 bar max., 400 bar peack; max. output speed 4.000 rpm; various controls options; SAE shafts and mounting flanges.

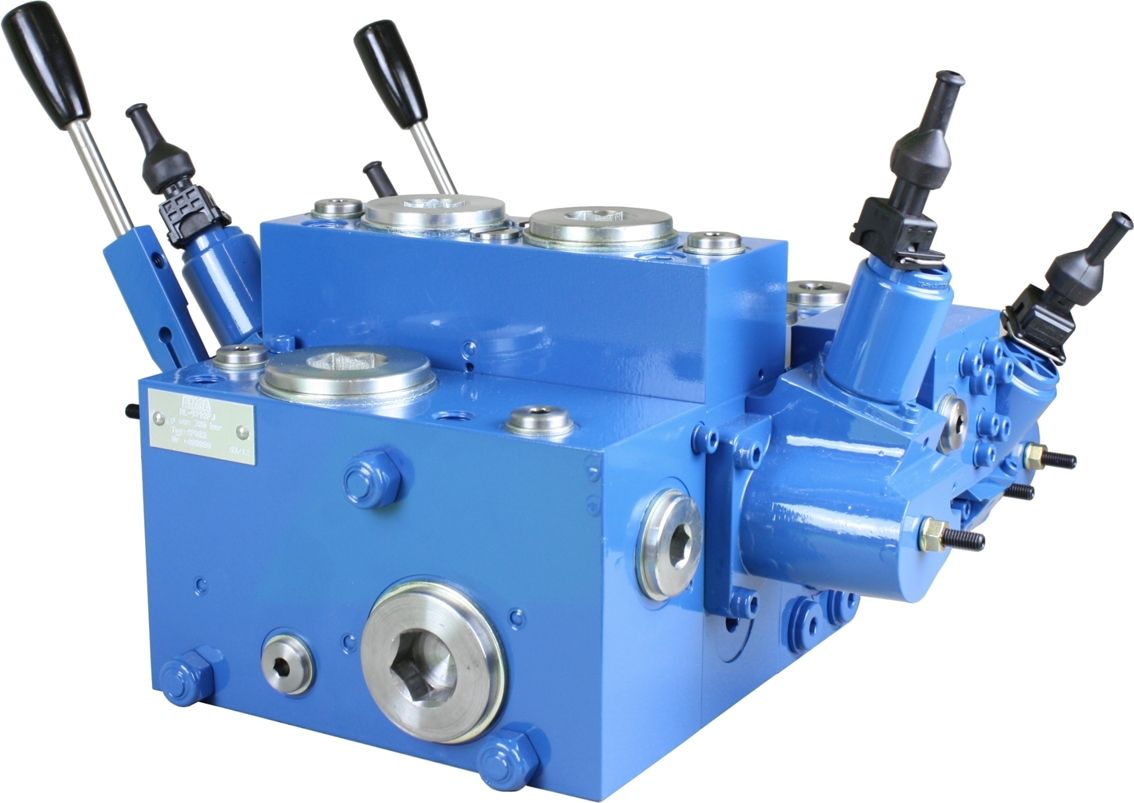

Closed center "load-sensing" sectional configuration; max. inlet flow 260 l/min and 120 l/min per section; max. working pressure 420 bar; manual, hydraulic and electro-hydraulic control; also available in kit form.

Closed center "load-sensing" sectional configuration; max. inlet flow 520 l/min and 330 l/min per section; max. working pressure 420 bar; manual, hydraulic and electro-hydraulic control; possible combination with AP16 valve sections; also available in kit form.

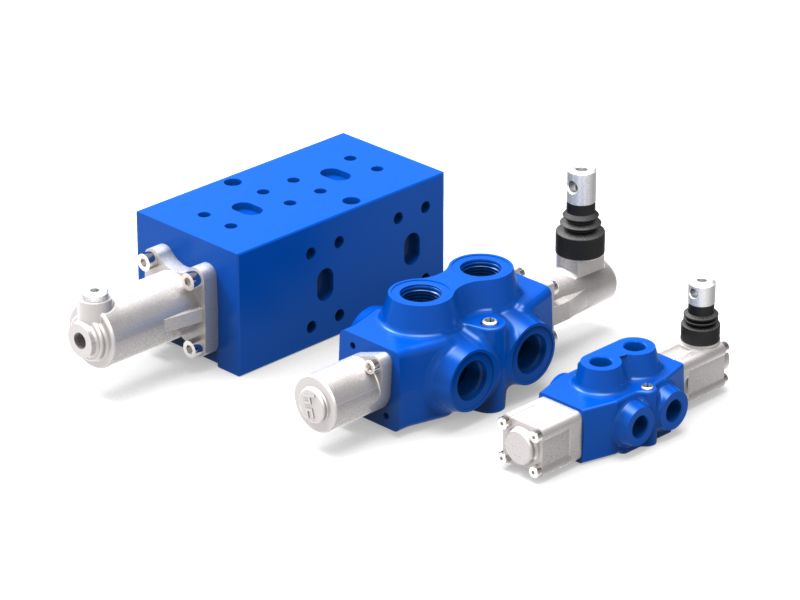

Flow range from 50 up to 350 l/min; maximum pressure 350 bar; port size 3/8"-1/2"-3/4"-1"1/4; manual and hydraulic control.

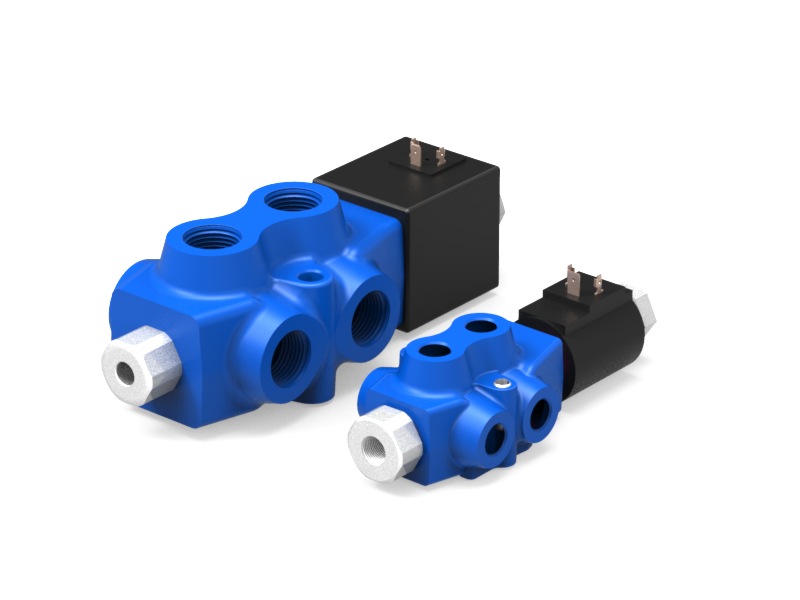

Flow range from 30 up to 100 l/min; maximum pressure 350 bar; port size 3/8"-1/2"-3/4"; electric “on-off” control

.

Flow range from 35 up to 120 l/min; maximum pressure 350 bar; port size 3/8"-1/2"-3/4"; manual control

.

Complete range of Spin-On filters suitable for low pressure for both suction and return lines; max. pressure 14 bar; max. flow 460 l/min; ports BSP, NPT, SAE; optional visual indicators.

Return line filters for tank top mounting; max. flow 500 l/min; max. pressure 16 bar; port size from 3/4" up to 2" BSP; hydraulic mineral oils; by-pass valve and visual or electrical clogging indicators.

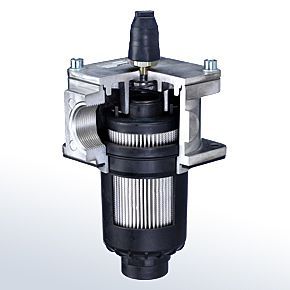

Tank top or in-line mounting; aluminium filter housing; max operating pressure 25 bar; nominal flow rate mx. 110 l/min; connection SAE O-ring thread; vsual clogging indicator or electrical clogging switch; hydraulic mineral oils

.

Return line tank mounted filter; aluminium head housing; nominal max. flow 185 l/min; max. operating pressure 10 bar; connecting ports from 3/4" up to 1" BSP; by-pass valve and visual or electric clogging indicators; hydraulic mineral oils.

Tank top or in-line mounting filters; carbon steel housing; operating pressure max. 25 bar; nominal flow max. 1.135 l/min; connection BSP or SAE flange (3000 psi); bypass valve, visual clogging indicator or electrical clogging switch; hydraulic mineral oils

.

Range of 5 sizes of return line filters tank mounted plus an insert design option; max. nominal flow from 95 up to 500 l/min; max. nominal pressure from 3,4 up to 10 bar; ports from 1/2" up to 1"1/2 BSP; by pass valve and visual or electrical clogging indicators.

In-line mounting medium pressure filters designed for hydraulic or lubrication systems; aluminium body; high dirth holding capacity filter elements; max. nominal flow 90 l/min; max. nominal pressure 110 bar; 1/2"BSP ports; by-pass valve and visual or electric clogging indicators.

In-line mounting medium pressure filters designed for hydraulic or lubrication systems; aluminium body; max. nominal flow 240 l/min; max. operating pressure 160 bar; 3/4" and 1" BSP ports or SAE threaded flange; by-pass valve and visual or electric clogging indicators.

In line high pressure filters for hydraulic and lubrication systems; filter head in cast iron and filter bowl in steel; max. nominal flow 1.135 l/min; max. operating pressure 420 bar; ports from 1/2" up to 1"1/2 BSP or SAE flanged (6000 psi); bypass, reverse flow, non-return or multi-function valve; visual, electrical or visual-electrical differential pressure indicator

.

In line high pressure filters for hydraulic and lubrication systems; manifold mounting design avalable in 2 options RH and LH; filter head in cast iron and filter bowl in steel; max. nominal flow 1.135 l/min; max. nominal pressure 315 bar; bypass, reverse flow, non-return or multi-function valve; visual, electrical or combined differential pressure indicators

.

In line high pressure filter designed for sandwich plate mounting, for hydraulic and lubricating systems, available in RH or LH options; max. nominal flow 30 l/min; max. operating pressure 315 bar; head and bowl in steel; bypass, reverse flow, non-return or multi-function valve; visual, electrical or combined differential pressure indicators.

Offline filter units suitable industrial hydraulic and lubrication systems; reduction of the contamination class level and absobtion of the water content in the fluid of the main circuit; external motor/pump unit with continuos filtration even when the main system is not in use. Nominal flow rate from 2 up to 20 l/ max. system fluid volume 10.000 l; port connections 3/8", 1/2" and 3/4 BSP; high dirth holding capacity filter elements

.

Mobile filtration systems are essential for the first load of hydraulic or lubricating fluids in new plants, for their testing and for their periodic maintenance. The SMFS-U-CM-110 flushing trolley is equipped with an electric motor of 4 kW @ 1,450 rpm, 400 VAC-50 Hz, a pump flow rate of 110 l / min, with filter elements of 3 to 25 μm absolute, with electric indicator and with 8-channel contamination class integrated control meter for accurate and continuous monitoring of the filtration process; weight of the cart is 177 Kg. Various other variants available and personalization even with low and high pressure separated circuits.